The basis of any plumbing or drainage system deployed in homes, commercial areas and industrial areas are made of pipes. In a case of water supply and waste removal, quality of pipes has a direct influence on safety, durability and long term performance. The decision regarding the appropriate type of pipe material is not a minor one as the inappropriate choice may result in leakage, the frequent repairs of systems and failure over time. CPVC Pipes, UPVC Pipes and SWR Pipes are among the most widely used piping solutions in India and each one is designed to serve a specific purpose.

We, at Flowtek Pipes & Fittings, understand that builders, contractors and homeowners often feel confused when comparing CPVC vs UPVC Pipes or deciding whether SWR Pipes are suitable for their project. Every pipe type has unique properties related to temperature pressure and application. Knowing how these pipes perform in real conditions helps you make a confident choice that saves money and avoids future issues. This detailed guide explains the differences in application manufacturing process and benefits of CPVC, UPVC and SWR Pipes in simple and practical terms.

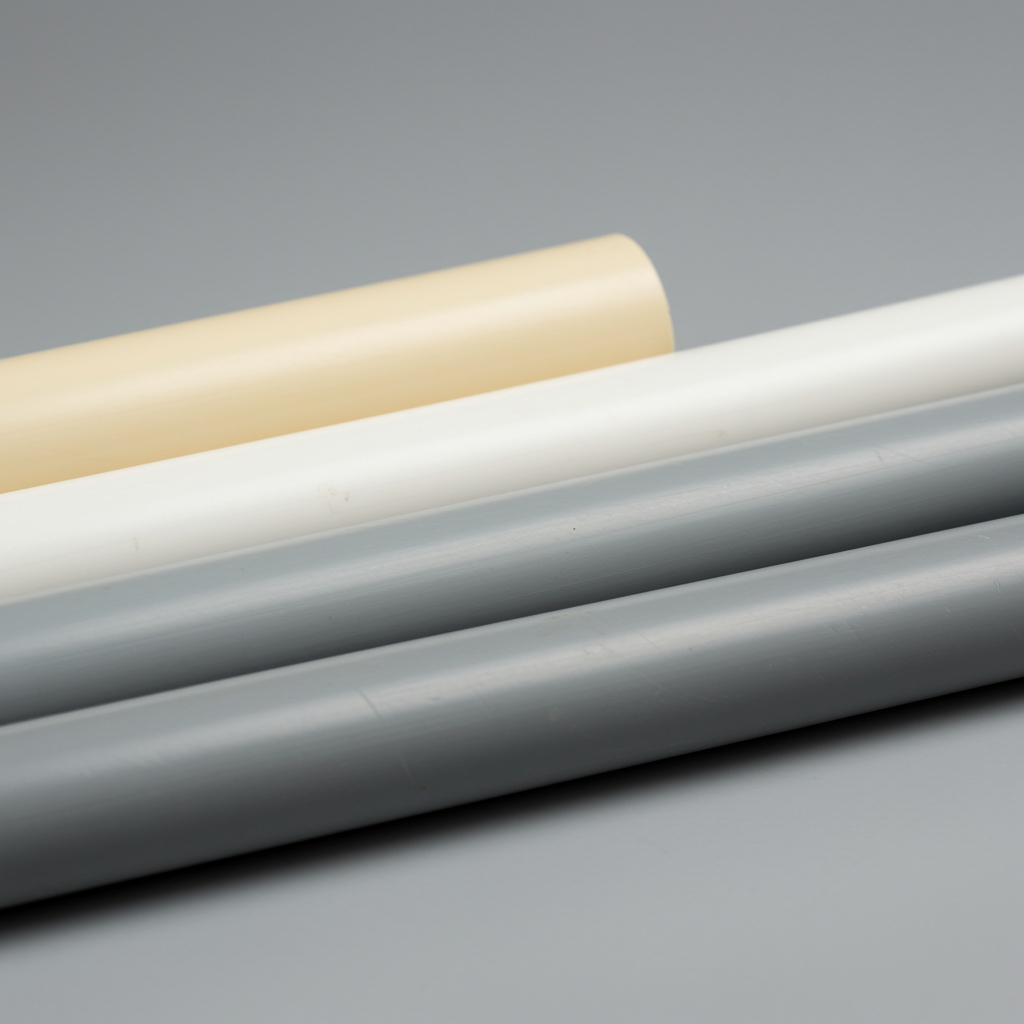

What Are CPVC, UPVC and SWR Pipes

CPVC Pipes

- CPVC Pipes are an advanced form of PVC pipes that are specially treated to handle high temperatures and pressure

- These pipes are widely used for hot and cold water supply in residential buildings, hospitals, hotels and industrial plants.

- CPVC Pipes maintain their strength even when exposed to hot water which makes them reliable for long term use.

- Flowtek Pipes & Fittings manufactures CPVC Pipes that offer excellent corrosion resistance, smooth flow and consistent performance across demanding environments

UPVC Pipes

- UPVC Pipes are rigid, strong and highly resistant to chemical corrosion

- They are mainly used for cold water supply drainage and irrigation systems

- These pipes are lightweight which makes installation easier and faster

- UPVC Pipes are a popular choice for residential and commercial plumbing because they require minimal maintenance and provide dependable service over many years

SWR Pipes

- SWR Pipes are designed specifically for soil waste and rainwater applications

- These pipes ensure efficient disposal of wastewater sewage and rainwater without leakage

- SWR Pipes are made from high grade PVC material that provides smooth internal surfaces and strong joints

Flowtek Pipes & Fittings produces SWR Pipes that support uninterrupted flow and long lasting durability in drainage systems

How CPVC, UPVC and SWR Pipes Are Manufactured

High quality pipes depend on precision manufacturing and strict quality standards. Trusted manufacturers like us, Flowtek Pipes & Fittings follow advanced processes to ensure strength accuracy and reliability that are :-

Extrusion Process

- The raw PVC or CPVC resin is heated and passed through extrusion machines to form pipes with uniform diameter and thickness

- This step ensures structural consistency throughout the pipe length

Vacuum Sizing and Calibration

- After extrusion the pipes pass through vacuum sizing tanks that maintain exact shape and roundness

- This process helps achieve tight fittings and leak free connections

Additive Blending

- Certain Additives are inserted depending on the type of pipe

- CPVC Pipes are stabilized to make them heat resistant

- The UPVC Pipes contain UV resistant compounds

- The reinforcement of SWR Pipes is done with impact modifiers in order to handle outside pressure

Surface Finishing

- The inside of the pipe is smoothed to minimize the friction and enhance flow

- This is reinforced to the outer skin to avoid any damage in the course of handling and installation

Important Issues in the Choice of Pipes

The selection of the right pipe involves real world conditions and needs of use.

- Hot water systems that use CPVC Pipes are the best in temperature resistance

- Pressure management is important within multi storey structures and industrial designs

- The chemical resistance is necessary in places with treated water or effluents

- The cost of labor and project schedule are influenced by installation ease

- Maintenance and Lifespan is determined by the quality of materials and adherence to their standards

Flowtek Pipes and Fittings assists customers to consider such aspects in ensuring the appropriate solution in terms of piping at any given application in any industry.

The Materials in CPVC, UPVC and SWR Pipes

- CPVC Pipes chlorinated high temperature resin PVC is used

- The UPVC Pipes come in form of rigid PVC which is improved with UV and chemical stabilizers

- SWR Pipes also incorporate the use of impact resistant PVC resin in waste and rainwater system

These materials are safe and durable and have efficient performance in everyday use.

CPVC, UPVC and SWR Pipes in Use

CPVC Pipes Applications

- Supply of hot and cold water in the homes and apartments

- Hot water circulation in industries

- Hotels and commercial buildings hospitals

UPVC Pipes Applications

- Cold water plumbing

- Rainwater collecting systems

- Irrigation systems and agriculture

SWR Pipes Applications

- Sewage and Waste Disposal

- Rainwater Drainage Systems

- Management of Industrial effluents

Every type of pipe has a definite purpose that makes it necessary to choose the type of the pipe correctly.

Facility Capability and Benefits

- Advanced extrusion and calibration techniques are used in the production of CPVC Pipes and this gives them high temperature resistance and long service life

- These pipelines are best to use in case of hot water supply and industrial pipelines which provide low maintenance and high safety

- The UPVC Pipes are manufactured using UV stabilizers and finish finishing thus making them lightweight strong and chemical resistant

- They are applicable in cold water plumbing and rain water systems and they are cost effective and easy to install

- SWP Pipes are vacuum sized and reinforced with impact techniques which would guarantee smooth flow and leak proof drainage

- They can be used in sewage and rainwater disposal with a high degree of reliability in its operation and low chances of blockage

- All pipes provided by Flowtek Pipes and Fittings are highly checked based on their strength against pressure correct dimension and resistance to chemical to provide constant reliability in the long run

Measuring and Quality Control

One of the most important steps in manufacturing pipes is quality testing.

- The pressure testing ensures that the working pressure is within the capability of the pipe

- Impact resistance is that of guaranteeing durability during usage

- Checks dimensional ensure proper diameter and thickness

- Chemical resistance tests confirm the safety in different water conditions

Flowtek Pipes & Fittings practices high quality control in order to provide customers with the pipes that satisfy the industry standards and expectations.

The Benefits of CPVC, UPVC and SWR Pipes

- CPVC Pipes are used to supply high temperature water and have a lifespan of years against corrosion

- UPVC Pipes are cheap light and durable

- SWR Pipes will guarantee smooth flow of waste and drainage that is leak free

- The general advantages are reduced maintenance easy installation and long term efficiency

The appropriate pipe is found to ensure that the cost of operations is minimized and the performance of the system is enhanced.

Conclusion

All three types of pipes CPVC, UPVC and SWR Pipes have an important role in the modern plumbing and drainage systems. CPVC Pipes are best used in hot water systems UPVC Pipes are used in cold water supply and SWR Pipes are used in wastes and rainwater. The correct decision would be safe, durable and cost effective to any project.

Flowtek Pipes and Fittings deal with high quality CPVC Pipes, UPVC Pipes and SWR Pipes which are specific to the various project requirements. Being a reputable SWR Pipes Supplier in India the we assists the builders and contractors with quality and reliable products expert advice and quality assurance over long duration to achieve success.